FAQ's

How do I determine the right panel and load tolerance for my project?

When designing the access floor component of your project, it is important to answer the following:

- Where will the access floor be located?

- What will be placed on the access floor?

- What are the loads that will be placed on the access floor during construction as well as the loads placed on the floor during occupancy?

Analyzing and determining the required properties of the access floor in terms of their structural performance, resistance, air leakage requirements, acoustic performance, etc in these early stages will help ensure that the correct panel type, load grade, and understructure system is applied to your project.

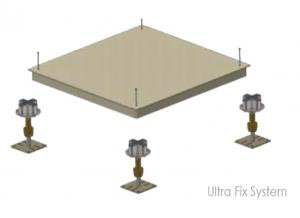

How are panels attached to the understructure?

ASP access floor panels are either:

Screw fixed

Screw Fixed Panels are assembled onto an ultra-fit or core rigid system. Panels are screwed into the pedestal heads.

Gravity fixed

Gravity Fixed Panels are assembled onto a Rigid Grid system with HPL, vinyl, rubber, or timber finish. Panels are supported on all four sides by a stringer.

How can we be assured that our floor will be level if the subfloor is uneven?

When an ASP Access Floor is installed, our installers use laser levels to ensure that the surface of the floor is level at the required FFH, regardless of undulations in the subfloor. Using the height-adjustable pedestals, our installers can raise and lower the panel in order to obtain a level finish.

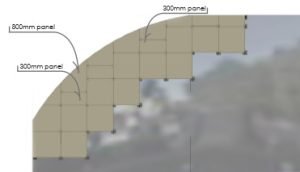

How do you support small panel cuts when the floor meets a perimeter or supporting column?

ASP has developed 300mm and 800mm finishing panels to meet the desired lengths at a perimeter, in order to eliminate smaller cuts. When an access floor meets an unusual shape or structure, panels are cut to shape and size with supplementary support pedestals used to improve strength.

What finishes are available for my access floor?

Factory-applied finishes:

- Anti-static high-pressure laminate

- Anti-static Vinyl

- Vinyl and Marmoleum

- Timber

- Stone

- Ceramic Tiles

Site applied finishes by others:

- Carpet

- Sheet Vinyl

- Stone

- Tiles

- Timber

What is the acoustic rating of an access floor?

ASP Access floors have been tested in accordance with AS/NZ ISO 717.1:2004: Rating of sound insulation in buildings and of building elements- Airborne sound insulation; and AS/NZ ISO 717.2:2004 Rating of sound insulation in buildings and of building elements- impact sound insulation.

What are the advantages in regards to services if I use an access floor?

Ventilation, as well as power/data, is capable of being installed under the floor, with outlets fitted in the access floor panel.There are many advantages with running these services under floor such as:

- Ease of service and accessibility.

- Simple to rearrange services.

- Air conditioning is achieved through displacement as opposed to dilution.

- More cost-effective during installation and servicing.

What are zinc whiskers and will I ever have an issue with them if I have an ASP Access Floor product?

Zinc Whiskers are tiny conductive filaments of zinc typically less than a few mm long and a thousandth of an mm in diameter. They grow from metal surfaces that have been electroplated/ galvanized with zinc for corrosion protection. Zinc Whiskers are conductive and therefore will cause electrical shorts if they manage to bridge across tightly spaced electrical conductors.

All the ASP products are coated with a finish resistant to the growth of zinc whiskers. For specialized sensitive areas such as clean rooms and data centers, ASP has introduced powder coating panels, pedestal tubes and base, hot-dipped galvanized stringers as well as nickel-chrome platted pedestal heads, threaded rod, and nuts.

What are the earthing capabilities of the access floor?

By connecting a grounding cable to the pedestal head, an access floor can be grounded. However, the frequency of the grounding varies depending on understructure and panel type. These calculations should be carried out by an electrical engineer and installed by an electrician.

What is the fire rating of an access floor?

Access floors are not fire rated, instead, they are tested for their resistance to fire. ASP was tested and complied with AS ISO 9239: reaction to fire test for flooring.

What is the process of installation for an access floor?

When installing an access floor, much planning and a thorough understanding of the building site are required. Installing an access floor requires the co-operation of the head contractor, access floor installer, and other associated trades, to make sure that all works run smoothly and on schedule.

To ensure that the access floor works are installed to the requirements of your program the following guideline should be adopted:

- Planning how the access floor materials will be loaded onto the working zones; i.e. goods lift, crane, builders hoist, etc.

- Planning a material path from the truck to the access floor area, it is recommended that there should be a free path from an elevator and/ or hoists to the area receiving the access floor material.

- A dry and secure storage area should be made available to store access floor materials. It is desired that the storage area be unaffected by weather.

- Co-ordinate a work schedule with other working trades. All overhead works should be completed prior to the access floor installation. If overhead works are installed after access floor works, the access floor must be adequately protected to prevent damage, a minimum of 25mm thick plywood is recommended to be placed on top of the access floor.

- Working area is to be swept clean, mark the set-out points and then seal with approved ASP floor sealer.

- For high service traffic areas a set out can be incorporated to ensure that the service trades work according to the access floor grid.

- Service trades and access floor installers work in conjunction with each other.

- Floor signed off by a head contractor.

Australian And International Standard Tests:

The Australian standard and International standard tests that the access floors is manufactured to comply with are as follows:

- AS4154-1993 – General Access Floors (elevated floors)

- AS4155.0-1993 – Test Methods for General Access Floors part 0: Introduction and list of methods

- AS4155.1-1993 – Test for concavity and convexity

- AS4155.2-1993 – Test for a twist

- AS4155.3-1993 – Test for panel squareness

- AS4155.4-1993 – Test for the effect of temperature

- AS4155.5-1993 – Test for the effect of humidity

- AS4155.6-1993 – Test for floor resistance and electrostatic control

- AS4155.7-1993 – Test for 300mm x 300mm concentrated load

- AS4155.8-1993 – Test for 25mm x 25mm concentrated load

- AS4155.9-1993 – Test for ultimate load test (safety factor tests for concentrated load)

- AS4155.10-1993 – Test for dynamic soft body impact load

- AS4155.11-1993 – Test for dynamic rolling loads with the tread made from resinous polymer

- AS4155.12-1993 – Test for pedestal strength by the concentrated vertical load

- AS4155.13-1993 – Test for pedestal free movement by horizontal load

- AS4155.14-1993 – Test for pedestal strength by horizontal movement

- AS1170.0-2002 – Structural Design Actions: General Principles

- AS1170.0-2002 – Structural Design Actions: Permanent, imposed, and other actions

- AS1170.4-2002 – Structural Design Actions: Earthquake Actions in Australia

- ISO9239-1-2003 – Reaction to fire tests for flooring: Determination of the burning behavior using a radiant

heat source - EN12825-2001 – Reaction to fire Classification A1

- DIN 4102-1-1998 – Fire Behaviour of Building Materials and Elements

ASP is also compliant with CISCA, PSA, and DIN standards.

The Australian standard and International standard tests that the access floors are manufactured to comply with are as follows:

- AS4154-1993 – General Access Floors (elevated floors)

- AS4155.0-1993 – Test Methods for General Access Floors part 0: Introduction and list of methods

- AS4155.1-1993 – Test for concavity and convexity

- AS4155.2-1993 – Test for a twist

- AS4155.3-1993 – Test for panel squareness

- AS4155.4-1993 – Test for the effect of temperature

- AS4155.5-1993 – Test for the effect of humidity

- AS4155.6-1993 – Test for floor resistance and electrostatic control

- AS4155.7-1993 – Test for 300mm x 300mm concentrated load

- AS4155.8-1993 – Test for 25mm x 25mm concentrated load

- AS4155.9-1993 – Test for ultimate load test (safety factor tests for concentrated load)

- AS4155.10-1993 – Test for dynamic soft body impact load

- AS4155.11-1993 – Test for dynamic rolling loads with the tread made from resinous polymer

- AS4155.12-1993 – Test for pedestal strength by the concentrated vertical load

- AS4155.13-1993 – Test for pedestal free movement by horizontal load

- AS4155.14-1993 – Test for pedestal strength by horizontal movement

- AS1170.0-2002 – Structural Design Actions: General Principles

- AS1170.0-2002 – Structural Design Actions: Permanent, imposed, and other actions

- AS1170.4-2002 – Structural Design Actions: Earthquake Actions in Australia

- ISO9239-1-2003 – Reaction to fire tests for flooring: Determination of the burning behavior using a radiant

heat source - EN12825-2001 – Reaction to fire Classification A1

- DIN 4102-1-1998 – Fire Behaviour of Building Materials and Elements

ASP is also compliant with CISCA, PSA, and DIN standards.

If You Have Any Questions,

Call Us on (+64) 9 579 4799

or fill in our enquiry form and we will endevour to be in touch in the next 24 hours.